Food safety isn't just a list of rules—it's the bedrock of your restaurant. These guidelines are the daily actions that prevent foodborne illness, covering everything from handwashing and temperature control to deep cleaning and staff training. Following them protects your customers and builds the trust that keeps them coming back.

Build a Food Safety Culture, Not a Checklist

Real food safety isn't about a checklist. It's about building a culture where every team member—from the head chef to the newest hire—instinctively knows their role in protecting guests. It’s about moving past a "good enough to pass" mindset and embedding safety into your kitchen's DNA.

Think of it this way: a checklist helps you inspect your defenses, but a strong culture ensures every guard is always vigilant. The goal is to make safe practices automatic, not an afterthought.

Why It Matters

You can't ignore the stakes. The World Health Organization estimates that contaminated food makes 600 million people sick each year, leading to about 420,000 deaths. For a restaurant, these aren't just statistics; they're a direct threat to your customers' health and your business's future.

This guide gives you the blueprint to build a rock-solid food safety system, turning compliance from a chore into a competitive advantage.

A strong food safety culture turns every employee into a guardian of public health. It’s the difference between passing an inspection and earning unwavering customer loyalty.

The Four Pillars of Restaurant Food Safety

A robust food safety program stands on four critical pillars. Get these right, and every meal you serve will reflect your commitment to excellence.

This table gives you a quick overview.

| Pillar | Core Principle | Primary Goal |

|---|---|---|

| Hazard Control | Identify and manage risks at every step. | Prevent food safety issues before they start. |

| Temperature Management | Use precise temperature to stop bacterial growth. | Keep food out of the "danger zone" at all times. |

| Sanitation Protocols | Eliminate pathogens with strict cleaning and pest control. | Maintain a hygienic environment everywhere. |

| Team Training | Empower staff with knowledge and skills. | Make food safety a shared, second-nature responsibility. |

By focusing on these four pillars, you build a comprehensive system that protects your guests, your team, and your reputation.

Here’s what each pillar looks like in action:

-

Proactive Hazard Control: This is about thinking ahead. Identify potential risks before they become problems, tracking every ingredient from delivery to the final plate.

-

Strict Temperature Management: Temperature is your best weapon against bacteria. Precise control during storage, cooking, and holding is non-negotiable.

-

Flawless Sanitation Protocols: A kitchen that looks clean isn't enough. Real sanitation eliminates invisible threats. This demands diligent cleaning schedules, the right chemicals, and proper pest control. Air quality is often overlooked; our guide on commercial fly fans can help you create a pest-free zone.

-

Continuous Team Training: Your team is your first line of defense. Consistent training ensures everyone understands the "why" behind the rules, giving them the confidence to make the right call every time.

Your HACCP Plan in Action

Hazard Analysis and Critical Control Point (HACCP) sounds complex, but it's just a smart, proactive system for food safety. Think of it as a personalized safety map for every ingredient, helping you spot dangers before they become problems.

Instead of just reacting to issues, a solid HACCP plan is all about prevention. It turns complex rules into simple, repeatable steps that become part of your kitchen's daily rhythm.

The 7 Principles: Your HACCP Building Blocks

HACCP is built on seven core principles. Use them to design a safety system tailored to your menu, equipment, and staff. It all starts with one question: "What could go wrong with this ingredient?"

Answering that question is the first step toward building a rock-solid defense against foodborne illness.

Here’s how to apply these seven principles in your kitchen:

-

Conduct a Hazard Analysis: This is your reconnaissance. Follow an ingredient, like raw chicken, through your kitchen. Identify every point where a biological, chemical, or physical hazard could be introduced.

-

Pinpoint Critical Control Points (CCPs): A CCP is a make-or-break moment where you can eliminate a hazard. The classic example is cooking raw meat—this is your chance to kill harmful bacteria.

-

Set Clear Critical Limits: Every CCP needs a non-negotiable boundary. For that chicken, the critical limit is an internal temperature of 165°F (74°C). It's a hard rule, not a suggestion.

From Plan to Practice: Controls and Monitoring

Once you've mapped out hazards and set limits, it's time to bring the plan to life. This means creating clear, consistent procedures your team can follow without fail, even during a chaotic Saturday night service.

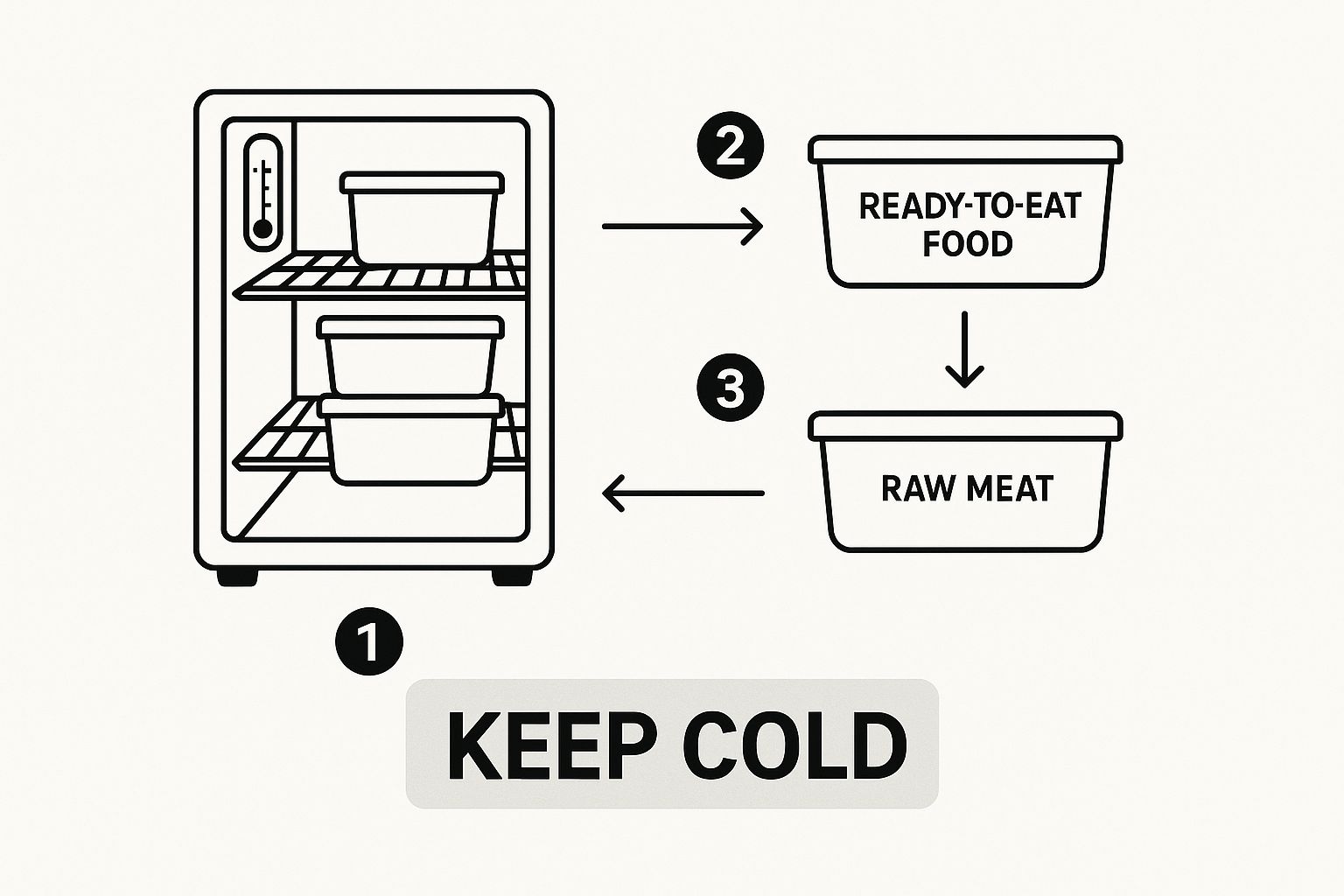

This image shows a perfect example of a CCP: cold storage. The critical limit is keeping food below 40°F, a simple but vital safety step.

As the infographic shows, visible thermometers and clear labels are essential tools for monitoring your CCPs effectively.

The final four principles turn your HACCP plan into a living system:

-

Establish Monitoring Procedures: How will you check that limits are being met? Decide who checks the temperature, how often, and what tool they use, like a calibrated food thermometer.

-

Set Up Corrective Actions: Have a plan for when things go wrong. If the chicken only temps at 155°F, the corrective action is clear: keep cooking it until it hits 165°F. Your plan must have these "if-then" solutions ready.

A great HACCP plan doesn't just find problems—it gives your team the immediate solution. It removes guesswork and panic, so everyone knows exactly what to do when a safety limit isn't met.

-

Verify Your System Works: This is your quality control. Regularly double-check the system itself. A manager might review temperature logs nightly, or you could recalibrate thermometers weekly. Verification confirms your plan is working as designed.

-

Keep Good Records: Your documentation is your proof. Meticulous logs of temperatures, corrective actions, and training sessions are crucial. They create accountability and are your best defense during a health inspection, showing a consistent, professional commitment to food safety.

Mastering Critical Temperature Control

In the kitchen, temperature is your most powerful weapon against bacterial growth. Getting temperature management right isn't just a good idea—it's everything. Harmful bacteria are always looking for the right conditions to multiply. The right temperature stops them cold.

Let's walk through how to make temperature your greatest ally, from delivery truck to customer table.

Know the Temperature Danger Zone

If you remember one thing, make it this: the Temperature Danger Zone. This is the range where bacteria multiply rapidly.

The Temperature Danger Zone is between 40°F and 140°F (4°C and 60°C). Your number one job is to keep high-risk foods out of this range as much as possible.

Leaving raw chicken or a cream sauce in this zone is like leaving your front door unlocked overnight. You’re inviting trouble. Minimizing time in the danger zone is the bedrock of safe food handling.

Temperature Control From Start to Finish

Controlling temperature is a constant process. It starts the moment a delivery truck arrives and only ends when the plate is clean.

Don't miss these key checkpoints:

- Receiving: Get your thermometer out as soon as deliveries arrive. Cold foods must be 40°F (4°C) or below. Frozen items must be rock solid. Reject anything that doesn't meet these standards.

- Cold Storage: Your fridges must keep food at or below 40°F (4°C). Freezers must be at 0°F (-18°C) or lower. Use external thermometers to monitor temperatures at a glance without opening the doors.

- Thawing: Never thaw food on the counter. The only safe ways are in the refrigerator, under cold running water (70°F or below), or as part of the cooking process.

- Hot-Holding: If you're holding cooked food for service, it must stay at 140°F (60°C) or hotter. Check it regularly with a calibrated thermometer.

Cook to Minimum Internal Temperatures

Cooking is your final line of defense to kill pathogens. Different foods require different internal temperatures to be safe. Guessing or going by color is a dangerous game. A food thermometer is the only way to know for sure.

Here’s a quick-reference guide.

Minimum Internal Cooking Temperatures Guide

Hitting these numbers is non-negotiable for safety.

| Food Category | Food Item Examples | Minimum Internal Temperature |

|---|---|---|

| Poultry | Chicken, turkey, duck (whole, ground, or parts) | 165°F (74°C) for 15 seconds |

| Ground Meats | Ground beef, pork, veal, lamb | 160°F (71°C) for 15 seconds |

| Pork, Beef, Veal, Lamb | Steaks, roasts, chops | 145°F (63°C) for 15 seconds |

| Fish and Shellfish | Fish fillets, shrimp, lobster, scallops | 145°F (63°C) for 15 seconds |

| Leftovers & Casseroles | Any food being reheated | 165°F (74°C) for 15 seconds |

Always check the temperature in the thickest part of the food, avoiding bones or gristle for an accurate reading.

Thermometer Calibration and Modern Logging

An uncalibrated thermometer is useless. To check it, use the ice-point method: stick it in ice water and make sure it reads 32°F (0°C). If not, adjust it.

To upgrade your system, look into digital tools that automatically log temperatures 24/7. They can send an alert to your phone if a unit enters the danger zone, removing human error and ensuring perfect, compliant logs for health inspections.

Preventing Cross-Contamination in a Busy Kitchen

Cross-contamination is the invisible enemy. It happens when harmful bacteria travel from one food to another, usually on a contaminated surface, tool, or hands. A single slip-up here can cause a serious foodborne illness outbreak, even if every other rule is followed.

During a busy service, your kitchen is a fast-paced environment. Raw chicken is prepped here, fresh salad greens there. The #1 rule: these two worlds must never collide. This requires a system of separation and sanitation so ingrained it becomes muscle memory.

Create Clear Lanes for Food Safety

The best way to prevent cross-contamination is to create distinct zones and workflows for different food types. This starts the moment ingredients arrive and continues until the dish is plated. Give raw and ready-to-eat foods their own dedicated space, tools, and procedures.

A simple color-coded system is one of the most effective tools. It eliminates guesswork and makes the right choice the easy choice.

- Red for Raw Meat: Red cutting boards and knives for beef, pork, and lamb.

- Yellow for Raw Poultry: Yellow tools for all raw chicken, turkey, and duck.

- Blue for Raw Seafood: Blue boards and utensils for fish and shellfish.

- Green for Produce: Green equipment for all fruits and vegetables.

- White for Ready-to-Eat: White for foods that are good to go, like bread, cheese, and cooked items.

With a system like this, the board used for raw chicken won't be used for salad greens five minutes later.

Strategic Storage and Handling

Your defense plan must extend to your storage. How you organize your shelves is just as critical as your prep line. Smart organization prevents dangerous situations, like raw chicken juice dripping onto cheesecakes.

The rule is simple: store food based on its final cooking temperature. Ready-to-eat foods, which aren't cooked, always go on the top shelf. Raw poultry, which needs the highest cooking temperature, always goes on the bottom.

In the fridge hierarchy, ready-to-eat food is king and gets the top shelf. Raw poultry, needing the most thorough cooking, sits at the bottom. This simple storage logic is a powerful defense against cross-contamination.

The Human Element: Handwashing and Allergens

Even the best system can be defeated by human error. Hands are the #1 way contaminants spread. Strict handwashing is an absolute must. Staff must wash with soap and water for a full 20 seconds after handling raw meat, returning from a break, or even touching their face.

Allergen management is another critical piece. An employee who handles shellfish and then prepares a "gluten-free" dish without changing gloves and washing up can cause a life-threatening reaction. You need dedicated prep areas, utensils, and fryers for common allergens. Pests are another contamination vector, so keeping them out is vital. For more, our guide on fly control for restaurants can help secure your kitchen.

By weaving these habits—separation, smart storage, and relentless hygiene—into your daily operations, you build a powerful defense that protects every plate that leaves your kitchen.

Nailing Your Cleaning and Sanitation Game

There's a huge difference between a kitchen that looks clean and one that’s truly sanitary. A tidy kitchen can still be a playground for invisible pathogens. Nailing your cleaning and sanitation means going on the offensive against these microscopic threats, not just wiping up spills.

This means moving beyond surface-level tidying to a detailed, systematic plan that makes your kitchen a hostile environment for germs. It's about shifting from reactive cleanup to proactive safety.

Cleaning vs. Sanitizing: Know the Difference

People often use "cleaning" and "sanitizing" interchangeably. In a professional kitchen, they are two distinct and critical steps.

Cleaning is step one: physically removing food, dirt, and grease from a surface using soap and water. Sanitizing is step two, done after cleaning. It uses a chemical solution to kill germs and reduce them to a safe level. You cannot sanitize a dirty surface.

Think of it like washing your hands. You use soap and water to scrub off visible dirt (cleaning), then you might use hand sanitizer to kill any remaining germs (sanitizing). One removes the mess, the other handles the invisible danger.

Create a Master Cleaning Schedule

A top-tier sanitation program runs on a rock-solid master cleaning schedule, not memory. This is your kitchen's hygiene playbook, detailing every task so nothing gets missed. Post it where everyone can see it.

A great schedule breaks down jobs by frequency and responsibility.

- After Every Shift: Clean and sanitize all food-contact surfaces—cutting boards, prep tables, slicers. Sweep and mop floors and take out the trash.

- Weekly Deep Dives: Tackle bigger jobs. Deep clean ovens, fryers, and walk-in coolers. Delime sinks and faucets and scrub floor drains.

- Monthly Overhauls: Clean and sanitize ice machines and freezers. Wash down walls and ceilings and conduct a thorough pest inspection. A solid pest prevention plan is a huge part of sanitation; learn more in our guide on choosing a fly cover for food.

Using Chemical Sanitizers Correctly

Just spraying sanitizer isn't enough. To be effective, you have to use it right. The two most important factors are concentration and contact time. The pandemic drove home how crucial these protocols are, setting a new standard for preventing contamination.

Follow these steps every time:

- Check Concentration: Use test strips to ensure your chemical sanitizer is mixed to the correct strength. Too weak, and it won't kill germs. Too strong, and it could be a chemical hazard.

- Respect Contact Time: Every sanitizer needs a specific amount of time to sit wet on a surface to work. This contact time is usually between 30-60 seconds, but always read the manufacturer’s label.

- Air Dry: Once the contact time is up, let the surface air dry completely. Wiping it down can re-contaminate the surface you just sanitized.

Empowering Your Team with Effective Food Safety Training

Your food safety program is only as strong as the team running it. The best HACCP charts mean nothing if your staff doesn't understand the "why" behind the rules. Great training powers your entire food safety culture, turning guidelines into consistent, everyday actions.

Think of training as an ongoing conversation, not a one-time lecture. The goal isn't just memorization for an inspection; it's empowering your team to become active guardians of your standards, ready to make smart, safe decisions instinctively.

From Rules to Reflexes

A solid training program must cover the non-negotiables. Every team member, from the executive chef to the newest hire, needs to be fluent in the language of food safety.

This essential training must cover:

- Personal Hygiene: This is ground zero. It includes meticulous 20-second handwashing, correct glove use, and the importance of clean uniforms and hair restraints.

- Preventing Cross-Contamination: Your team must understand your systems, like color-coded cutting boards, and the absolute need to keep raw and ready-to-eat foods separate.

- Time and Temperature Control: Everyone must know the Temperature Danger Zone (40°F to 140°F) by heart and understand their role in keeping food out of it.

- Allergen Management: With food allergies on the rise, this is a life-or-death issue. Training must cover how to prevent allergen cross-contact and handle customer questions with total accuracy.

Making Food Safety Training Stick

The challenge isn't just delivering information; it's making it stick. A boring slideshow is forgotten during a busy service. Use engaging, varied methods to reinforce lessons over time.

Instead of one long session, break training into smaller pieces. A quick five-minute reminder on proper cooling methods during a pre-shift huddle is more effective than an hour-long presentation. This approach keeps food safety restaurant guidelines top-of-mind.

A well-trained team doesn't just follow rules; they understand the risks. They become proactive problem-solvers who can spot a potential safety issue before it becomes a threat.

The impact is huge. Studies show that dedicated food safety training reduces health code violations by about 50%. You can dive deeper into the findings on staff education and risk mitigation on nsf.org to see just how vital this is.

Ultimately, the goal is a culture where safety is a shared responsibility. When your team is confident and empowered to speak up, you've successfully turned your guidelines into a living practice that protects everyone who walks through your doors.

Your Top Food Safety Questions, Answered

Navigating the day-to-day realities of food safety can bring up tough questions. Here are answers to some of the most common ones.

What's the Single Biggest Food Safety Mistake?

Improper temperature control. It’s a silent threat that creeps in everywhere—from a delivery left on the loading dock too long to a steam table that isn't hot enough.

It’s easy to get distracted, but the Temperature Danger Zone (40°F to 140°F) is the perfect breeding ground for bacteria. Your calibrated food thermometer is your best friend. Use it constantly. Making temperature checks an unbreakable routine is the only way to operate safely.

How Detailed Does My HACCP Paperwork Need to Be?

Your HACCP documentation should be solid enough to prove you have a working system, but it doesn't need to be a novel. Think of it as the logbook for your food's safe journey. The goal is to keep clear, consistent records for your Critical Control Points (CCPs).

This includes:

- Temperature Logs: Simple, daily logs for all refrigerators, freezers, and hot-holding units.

- Corrective Action Records: A quick note of what went wrong (e.g., "chicken temped at 155°F") and how you fixed it ("returned to oven until 165°F").

- Supplier Information: Proof that you source ingredients from approved, reputable suppliers.

When an inspector arrives, they want to see that you have a system, you understand it, and you use it every single day. Digital logging tools can make this much easier.

Your documentation is your evidence. It’s proof that you actively manage risks every day, not just when an inspector is watching.

How Often Should My Team Really Get Food Safety Training?

Food safety training can't be a one-time event. To build a true safety culture, it has to be a constant conversation. A formal session is great for new hires, but after that, it's all about reinforcement.

A rhythm that works:

- Onboarding: Give every new team member a comprehensive food safety orientation before their first shift.

- Regular Refreshers: Hold a formal training session at least once or twice a year to review fundamentals and introduce new procedures.

- Daily Reminders: Use pre-shift huddles to share a quick safety tip—"Hey everyone, let's be extra careful about changing gloves between tasks today"—to keep it fresh.

This steady approach transforms food safety restaurant guidelines from a poster on the wall into an ingrained habit for your entire crew.

Keeping dining areas free from pests like flies is a critical, yet often overlooked, part of sanitation. The elegant and quiet fans from MODERN LYFE provide an effective barrier, protecting your food and ensuring your guests have a comfortable, pest-free experience. Explore our fly fan solutions today.