A commercial kitchen ventilation system is your first line of defense against the intense heat, smoke, and grease that define a busy kitchen. It's not just a fan—it’s the lungs of your restaurant. It works 24/7 to keep your staff safe, prevent fires, and ensure you meet health and safety codes.

Why Kitchen Ventilation Is More Than an Exhaust Fan

Most people see a metal hood and think it just pulls out hot air. That's part of the job, but a real commercial kitchen ventilation system is a much more critical piece of engineering. Think of it as a complete respiratory system for your building—constantly inhaling dangerous air and exhaling clean, fresh air to keep the entire space safe and breathable.

This isn't a "nice-to-have" feature; it's essential for any food service operation. It directly impacts everything from your team's health to your bottom line by handling several key tasks at once.

The Core Purpose of Kitchen Ventilation

A well-designed system is an integrated network built for safety and compliance. It's engineered to handle the tough conditions of a professional kitchen, and its main jobs are fundamental to your operation:

- Fire Prevention: The system’s main job is capturing flammable grease particles before they build up in your ductwork. This buildup is a primary cause of restaurant fires.

- Air Quality Control: It removes smoke, steam, and airborne contaminants that can cause respiratory issues, creating a safer and more productive work environment.

- Regulatory Compliance: A compliant system isn't optional—it's the law. It’s how you pass health and safety inspections and avoid heavy fines or shutdowns.

The global market for these systems is valued at around USD 4.30 billion, showing just how essential they are. That number is growing, driven by a booming food service industry and stricter regulations worldwide.

Never view a ventilation system as an isolated piece of equipment. It’s an active, dynamic system that interacts with your entire building, influencing everything from air pressure to your HVAC's effectiveness.

Investing in a high-performance system is an investment in your business's long-term health and safety. Proper airflow also helps control food odors that attract pests, making it a key part of your fly control for restaurants. Get your ventilation right, and you're not just clearing the air—you're building a safer, cleaner, and more profitable operation.

The Anatomy of a Commercial Kitchen Ventilation System

To understand how a commercial kitchen ventilation system keeps your space safe and clear, you need to know its parts. It's not just one big fan; it's a complete ecosystem where every component has a critical job. If one piece fails, the whole system suffers.

From the moment smoke leaves a hot grill to the instant fresh air enters the kitchen, this system is in constant motion. Let's break down how each component works together to handle the heat, grease, and smoke of a professional kitchen.

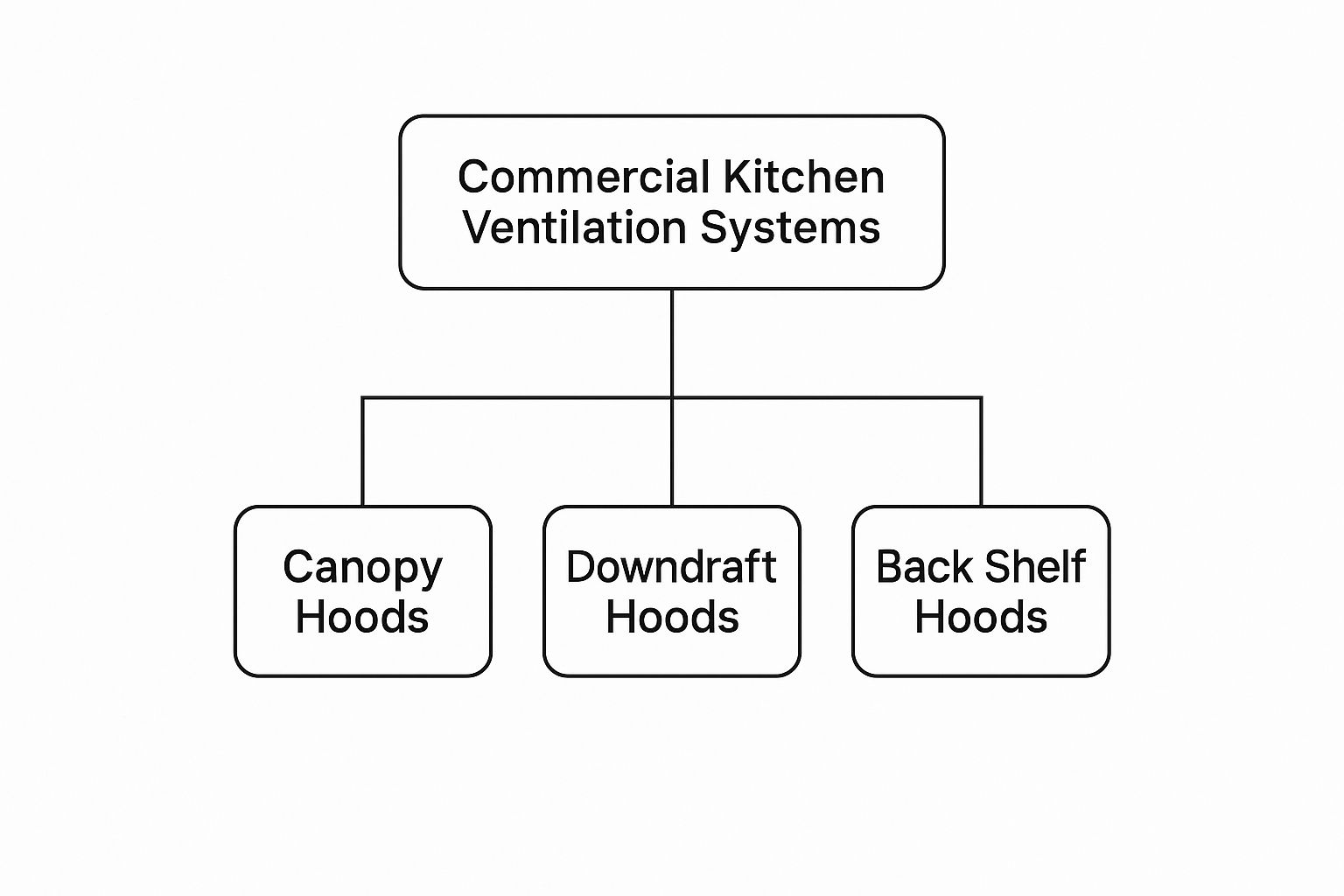

This breakdown shows the most common types of exhaust hoods—your first line of defense.

The hood's shape—whether it's a canopy, downdraft, or back shelf—is all about matching the right tool to the kitchen's layout and the equipment below it.

Here’s a simple look at how these pieces fit together.

| Component | Primary Function | Analogy |

|---|---|---|

| Exhaust Hood & Filters | Captures grease, smoke, and heat at the source. | The Catcher's Mitt of the system, snagging contaminants instantly. |

| Ductwork | Transports contaminated air out of the building. | The Superhighway, moving dirty air safely from Point A to Point B. |

| Exhaust Fan | Creates the suction needed to pull air through the system. | The Engine, providing the power that makes the entire system work. |

| Makeup Air (MUA) Unit | Replaces exhausted air with fresh, conditioned air. | The Lungs, breathing fresh air back in to keep everything balanced. |

Now, let's dive deeper into each component.

The Exhaust Hood and Filters

The exhaust hood is the most visible piece of the system. It's the metal canopy directly over your cookline—the grills, fryers, and ranges. Its purpose is to act as a funnel, capturing heat, steam, and greasy vapor before it escapes and coats your kitchen.

Inside the hood are the grease filters. These aren't simple screens; they are typically a series of stainless steel or aluminum baffles designed to pull airborne grease out of the air. As the fan pulls air upward, it forces it through these filters, which stop a huge amount of flammable grease from ever reaching the ductwork. This is the first critical step in fire prevention.

Ductwork: The System's Highway

After passing through the filters, the air enters the ductwork. Think of this as a dedicated highway system for kitchen exhaust. This network of sealed metal channels carries all captured contaminants from the hood, through the building, and out to the roof.

Proper ductwork is the unsung hero of kitchen safety. It must be built to handle high heat and corrosive materials. More importantly, it must be installed to meet strict fire codes, like those from the National Fire Protection Association (NFPA) 96, which dictate how it must be built and sealed to prevent grease buildup and fire risk.

A common mistake is assuming the filters catch 100% of the grease. They don't. A fine mist always gets through, which is why professional duct cleaning is absolutely critical. That hidden buildup inside the ducts is a major fire hazard.

The Exhaust Fan: The Driving Force

If the hood is the entry point and the ducts are the highway, the exhaust fan is the engine that makes it all work. This machine is usually mounted on the roof, where it creates the powerful suction needed to pull air from the cooktop, through the filters, up the ducts, and expel it outside. Without this fan, the system is just expensive sheet metal.

These fans are built to last, designed to run for hours while exposed to grease and weather. Their power is measured in cubic feet per minute (CFM), which is just the volume of air they can move. Getting the CFM right is crucial—too weak, and smoke fills your kitchen; too strong, and you're wasting energy.

The Makeup Air Unit: The Great Equalizer

Finally, we have the makeup air (MUA) unit. This component makes the ventilation a balanced, closed-loop system. The physics is simple: for every cubic foot of air you pull out of a room, an equal amount must come back in. The MUA unit does exactly that. It pulls fresh air from outside, often heats or cools it, and introduces it into the kitchen.

What happens without enough makeup air? You create negative air pressure, a vacuum effect that causes serious problems:

- Exhaust fans struggle: The fan can't pull air out effectively against the vacuum, leaving smoke and odors behind.

- Dangerous back-drafting: Gas appliances can have their exhaust, including deadly carbon monoxide, pulled back into the room.

- Doors become hard to open: The vacuum literally sucks them shut, creating uncomfortable drafts.

The MUA unit is the final piece that keeps the kitchen's air pressure neutral, ensuring everything works efficiently and the environment is safe and comfortable for your staff.

How to Choose the Right Exhaust Hood and Fan

Choosing the right exhaust hood and fan is one of the most important decisions you'll make for your kitchen. It’s not about aesthetics; it’s about matching the hardware to the heat and grease your cooking line produces daily.

This choice impacts everything from safety and efficiency to your ability to pass health and fire inspections.

You wouldn't use a small shop vac for a major construction site. Likewise, the hood for a couple of soup kettles is completely different from the heavy-duty system needed for a line of charbroilers and fryers. Getting this combination right is the foundation of a safe and effective ventilation system.

Hoods: Type I vs. Type II

Your first big choice is between a Type I and a Type II hood. This isn't a style decision—it's determined by what you're cooking.

A Type I hood is your workhorse. It’s engineered to handle grease-laden vapors from equipment like:

- Grills and charbroilers

- Fryers and griddles

- Ranges and woks

- Conveyor pizza ovens

Because they deal with flammable grease, Type I hoods are required by law to have integrated grease filters to trap particles before they enter your ductwork. The entire system, including the welded, leak-proof ducts, must follow strict fire safety codes like NFPA 96.

A Type II hood (or condensate hood) is for appliances that produce heat, steam, and odors but no grease. Think commercial dishwashers, pasta cookers, or certain ovens. Since there's no grease, there's no fire hazard, so the construction requirements are less strict, and they don't have grease filters.

The bottom line is non-negotiable: If it makes smoke or grease, you need a Type I hood. If it’s just heat and steam, a Type II will work. Getting this wrong is a serious safety hazard and a guaranteed code violation.

Matching the Fan to Your Hood

Once you have the right hood, you need the right engine: the exhaust fan. This is the powerhouse, usually on the roof, that pulls contaminated air out of the kitchen. The two most common types are upblast and downblast fans.

The upblast fan is the standard for any Type I system. It’s designed to shoot exhaust vertically, straight up and away from the roof. This is a critical safety feature that prevents flammable grease from collecting on your roof, which could cause a fire or damage roofing materials.

A downblast fan pushes air down onto the roof's surface. For this reason, it is unsuitable and non-compliant for any system handling grease. However, it's a fine and often cheaper option for Type II systems moving only clean steam and hot air.

The market for these systems is huge, reaching an estimated USD 1,538.41 million, because they are essential for commercial food service. In regions like North America, strict fire safety and air quality regulations keep demand high. You can learn more about these market dynamics to see how trends vary.

Key Factors for Your Final Decision

Before making a purchase, review these final checkpoints with your HVAC professional.

-

Analyze Your Cooking Line: List every piece of cooking equipment under the hood. The combined heat, smoke, and grease output determines the size and power (in CFM, or cubic feet per minute) your system needs.

-

Evaluate Your Kitchen Layout: The dimensions of your space matter. Ceiling height can dictate whether a standard canopy hood works or if you need a low-profile or back-shelf style.

-

Consider the Noise: High-powered fans can be loud. If your restaurant is near a residential area, you may need a quieter fan model or sound-dampening insulation to comply with local noise ordinances.

Getting the Design and Regulations Right

A top-tier commercial kitchen ventilation system is the result of careful engineering that balances performance, safety, and legal requirements. Getting the design phase right saves you from expensive fixes, hazardous conditions, or even a forced shutdown later.

This is about more than just picking a fan and a hood. It requires understanding airflow, equipment placement, and the web of codes every kitchen must follow. While you need a certified HVAC professional, knowing the fundamentals makes you a better partner in building a system that works for your business.

How Much Air Do You Need to Move?

The starting point for any design is calculating the required airflow, measured in cubic feet per minute (CFM). CFM is the system's raw power—the volume of air your fans must pull out every minute to remove heat, smoke, and grease. Too little power, and your kitchen becomes a smoky mess. Too much, and you're wasting money on energy.

Calculating the right CFM is a technical process based on key factors:

- Cooking equipment: A charbroiler or wok produces far more grease and heat than a steamer, requiring a much higher CFM.

- Hood size: A larger hood requires more air to create a strong, even pull across its entire surface.

- Kitchen layout: Your kitchen's setup can create unique airflow patterns that affect system performance.

Your HVAC contractor will calculate the exact CFM your kitchen needs, ensuring your system is powerful enough for the busiest rush without being an oversized energy hog.

Why Hood Overhang is Non-Negotiable

Once you know your CFM, the hood's physical size and placement are critical. To capture anything effectively, the hood must be larger than the cooking equipment beneath it. This is called hood overhang, and it's essential.

Think of it this way: you can't catch a downpour in a bucket that’s the exact size as the raincloud. It's the same in a kitchen. As smoke and hot air rise, they expand outward. A proper overhang—at least six inches past the edge of the equipment on all open sides—creates a wide enough "catchment area" for that expanding plume of greasy air.

Without enough overhang, you get "spillage"—grease-filled vapor escaping the hood and drifting into the kitchen. This defeats the purpose of the system, hurts your air quality, coats every surface in grime, and creates a serious fire hazard.

Following the Rulebook: NFPA 96 and Local Codes

The commercial kitchen industry operates under a strict set of rules, and the most important one is NFPA 96. This is the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations and serves as the bible for kitchen fire safety in North America. It outlines requirements for everything—duct construction, fan installation, cleaning frequency, and fire suppression integration.

NFPA 96 isn’t a suggestion; it's a standard with the force of law, and inspectors know it well. It’s the blueprint for preventing kitchen fires. If you don't meet its standards, you face failed inspections, fines, or a stop-work order. While this code covers ventilation, overall facility hygiene is also key. For instance, specialized door fans can keep bugs out and complement your safety protocols.

In addition to NFPA 96, you must follow local building, fire, and mechanical codes. These rules often use the NFPA standard as a baseline but may add stricter requirements. Your design team must be fluent in both national standards and local codes to avoid the nightmare of failing an inspection and having to redo new work.

Making Your Kitchen Smarter: Modern Ventilation Tech and Efficiency

A commercial kitchen ventilation system used to be a simple, fixed cost. Not anymore. Modern systems are more than a mandatory expense; they're smart tools for cutting energy costs and running a more sustainable kitchen.

Instead of running at full blast all day, new ventilation technology is an active, intelligent asset. It's the difference between leaving a light on in an empty room and having a motion sensor that turns it on only when needed. This approach saves energy and reduces equipment wear.

Demand-Controlled Kitchen Ventilation (DCKV)

The biggest game-changer is Demand-Controlled Kitchen Ventilation (DCKV). An old-school system is either on or off, running at 100% capacity all day, no matter what you're cooking. Searing a dozen steaks during the dinner rush? Full blast. Simmering one pot of stock? Still full blast. It's inefficient.

DCKV systems use smart sensors inside the exhaust hood to constantly monitor the heat and smoke from your equipment.

- During the Rush: When every burner is on, sensors detect the heat spike and ramp the fans up to full power to capture all the grease and smoke.

- During Slow Times: As service winds down, the sensors automatically slow the fans, sometimes by 50% or more.

This automatic adjustment means you're not wasting money blowing conditioned air out of your building when you don't need to. The electricity savings can be significant, often providing a quick return on investment.

A DCKV system ensures you're never paying to exhaust clean air. It aligns your energy use directly with your kitchen's actual output, minute by minute.

Capturing Lost Energy with Heat Recovery

Beyond smart fan control, modern systems can reclaim energy you're currently throwing away. A heat recovery unit captures the waste heat from the hot air being exhausted from your kitchen.

Instead of just pumping that valuable thermal energy outside, the system puts it back to work.

- Pre-heating Makeup Air: In colder climates, this is a huge advantage. The captured heat warms up the fresh makeup air, reducing the strain on your primary HVAC system and cutting your heating bills.

- Heating Water: The recovered heat can also be transferred to your water system, providing a steady supply of hot water for dishwashing and prep at little to no cost.

It’s a clever way to recycle energy, creating a closed loop that makes your entire operation more sustainable and cost-effective.

A Smart Investment in a Growing Market

Adopting these technologies is about more than immediate savings; it's about staying ahead of the curve. The industry is shifting toward greener, more efficient operations. The global market for commercial kitchen ventilation systems is projected to grow from USD 2.8 billion to roughly USD 4.7 billion by 2032.

This growth is driven by a massive demand for energy-efficient solutions. You can explore the full market forecast on dataintelo.com to see where the industry is headed. Investing in modern ventilation isn't just an equipment upgrade—it’s a move to future-proof your business.

Mastering Your Maintenance and Cleaning Schedule

Installing your commercial kitchen ventilation system is just the beginning. Think of it as a long-term commitment, not a one-time purchase. Consistent maintenance is what keeps the system running safely and efficiently for years.

Without a solid maintenance plan, even the best system will eventually fail. This isn't just about avoiding repairs; it's about protecting your staff, your investment, and complying with the fire code. A neglected system is a serious fire hazard.

Daily and Weekly Upkeep Tasks

Your first line of defense against grease is simple, daily habits. These tasks should be part of your kitchen's closing routine.

The most important daily task is cleaning your grease filters. These metal baffles are designed to catch flammable grease before it enters your ductwork. When clogged, airflow drops, your exhaust fan works harder, and the fire risk increases significantly.

The Necessity of Professional Cleaning

While your crew can handle daily filter cleaning, they can't reach the grease buildup deep inside the system. Tiny grease particles will always get past the filters, coating the inside of your hood and ductwork. This hidden residue is incredibly flammable and fuels most kitchen fires.

That's why professional hood and duct cleaning is non-negotiable. Certified technicians have the specialized equipment and food-safe chemicals to degrease everything from the hood to the exhaust fan on the roof. The National Fire Protection Association (NFPA) mandates cleaning frequency, which can be quarterly for a busy restaurant or annually for a low-volume kitchen.

Skipping a professional cleaning is one of the biggest risks you can take. The inside of your ductwork is out of sight, and that's exactly where the most dangerous fire hazards lurk.

Your Essential Maintenance Checklist

Beyond deep cleaning, you need to stay on top of the system's mechanical parts. Regular inspections can prevent a sudden breakdown during a dinner rush and extend the life of your equipment.

Your routine check-up should include:

- Fan Belts: Check for cracks, fraying, or looseness. A snapped belt will shut down your entire system instantly.

- Motor Inspection: Listen for unusual grinding or squealing noises. A little lubrication can prevent a total motor burnout.

- Makeup Air Filters: Check and replace dirty MUA filters. Clean filters ensure a steady supply of fresh air and protect your expensive HVAC system.

This proactive maintenance is a fundamental part of running a successful operation. To see how cleanliness impacts your entire business, check out our guide on essential food safety guidelines for restaurants.

Got Questions? We've Got Answers

It's normal to have questions about something as complex as a commercial kitchen ventilation system. Whether you're a new owner or a seasoned operator, getting straight answers is key. Here are some of the most common questions we hear.

How Often Does My Hood Need a Professional Cleaning?

There's no single answer. Your cleaning schedule depends on fire safety codes and, more importantly, what and how much you cook. The more grease you produce, the more often you need a professional cleaning.

Here's a general guide:

- Quarterly: For high-volume cooking. If you use wood-fired ovens, charbroilers, or woks, you're creating a lot of greasy vapor. A cleaning every 3 months is standard.

- Semi-Annually: This is the standard for most restaurants. If you do a moderate volume of frying, grilling, and sautéing, a deep clean every 6 months is usually required.

- Annually: For low-volume operations. Kitchens in places like churches, day camps, or senior centers can typically be cleaned once a year.

A certified professional can assess your setup and help you create a schedule that meets NFPA 96 standards and keeps your kitchen safe.

Remember, this isn't just about passing an inspection. The real goal is to remove the highly flammable grease that builds up deep inside your ductwork. That hidden gunk is the primary fuel for fires that can destroy a business.

Is Makeup Air Really That Important?

Yes, it's absolutely critical. Modern building codes require it for good reason. Your exhaust fan is a powerful vacuum, sucking huge volumes of air out of your kitchen. Makeup air is the fresh, clean air brought in from outside to replace it.

Without replacement air, you create negative pressure—a vacuum effect that causes chaos. Your hood will struggle to capture smoke and grease, leaving your kitchen hazy. Worse, it can cause gas appliances to back-draft, pulling lethal carbon monoxide back into the room where your staff is working. A properly balanced system isn't a luxury; it's a non-negotiable part of a safe kitchen.

Can I Just Install a Ventilation System Myself?

In a word: no. This is not a DIY project. Installing a commercial kitchen hood system is a highly specialized job requiring a deep understanding of fire codes (like NFPA 96), electrical work, and complex airflow dynamics.

A professional installation ensures everything is sized, sealed, and balanced correctly for safety and performance. A DIY job is a serious fire hazard waiting to happen. It will fail inspections, create a dangerous work environment, and ultimately cost far more to fix than hiring a certified pro in the first place.

At MODERN LYFE, we understand that a great dining experience depends on a comfortable and safe environment. While our expertise is in keeping your front-of-house breezy with our stylish fly fans, we know that true safety begins in the heart of the kitchen. See how our innovative solutions can elevate your guests' comfort at https://modernlyfe.com.