Restaurant health code violations are failures to meet food safety rules set by local, state, or federal authorities. These regulations cover everything from food storage temperatures to employee hygiene. Slipping up can mean fines, temporary closures, and a hit to your reputation that's hard to recover from.

A Look Inside a Restaurant Health Inspection

Don't think of a health inspection as a pass-fail exam. It’s an audit of your entire system. The local health department isn't just looking for dirt; they're there to evaluate your whole operation to stop foodborne illnesses before they start. Every rule, from handwashing to sanitizing equipment, exists for one reason: public safety.

When an inspector steps into your kitchen, they're using a risk-management lens. Their job is to pinpoint any potential hazard that could make a diner sick. They’re trained to catch the small things a busy kitchen staff might overlook.

What Inspectors Are Really Looking For

Inspectors focus on the "why" behind each rule. They don't just check if a countertop is wiped down; they assess whether your cleaning methods actually kill dangerous bacteria. They’re not just checking dates on food labels; they're ensuring your food rotation system is solid enough to prevent pathogen growth.

They almost always zero in on a few key areas:

- Temperature Control: Is hot food staying hot and cold food staying cold? Keeping food out of the temperature "danger zone" is non-negotiable.

- Cross-Contamination Prevention: Are raw meats stored and prepped far away from ready-to-eat foods like salads?

- Staff Hygiene and Practices: Are employees washing their hands correctly and often? Are they using gloves properly?

- Facility Maintenance: This is a big one. They're checking for pests, making sure equipment is properly sanitized, and confirming the building itself is in good shape. This also includes crucial systems that affect air quality—learn more about the importance of commercial kitchen ventilation systems in our detailed guide.

A common myth is that violations only happen in obviously "dirty" kitchens. The truth is, some of the most severe health code violations are invisible. Bacteria can thrive on a cutting board that looks perfectly clean but wasn't sanitized correctly.

From Minor Fix to Major Problem

It's critical to understand that not all violations carry the same weight. A cracked floor tile is a minor fix. But storing raw chicken on a shelf above fresh salad greens? That’s a critical violation that could cause a foodborne illness outbreak. Inspectors prioritize these high-risk issues because they pose an immediate threat to your customers.

The secret to passing an inspection isn't a last-minute cleaning frenzy. It's about building consistent, foolproof safety habits into your daily routine. Once you understand what inspectors are looking for, you can stop reacting and start being proactive. This shift in mindset makes compliance part of your restaurant's culture, turning that dreaded inspection from a source of stress into a confirmation of the great work you're already doing.

The Big Four: Critical Violations to Watch Out For

When a health inspector walks through your door, they see everything. But their eyes are trained to spot a handful of high-risk issues known as critical violations. These aren’t small things like a scuffed floorboard; these are the problems that can directly lead to foodborne illness.

Mastering these core issues is the first step to building a kitchen that’s always inspection-ready.

The stakes are higher than ever. Post-pandemic, health departments are looking closer, and data pinpoints exactly where they're finding the most trouble. A review of 255 health departments showed that sanitization of food contact surfaces is the number one issue, appearing in about 20% of all inspections.

Other frequent critical violations follow closely, including improper cold holding temperatures (15.9%), poor handwashing (15%), and failing to separate and protect food from contamination (8.3%). The most shocking part? A staggering 66% of these common violations fall directly into the critical foodborne illness risk category. You can read the full post-pandemic compliance report to see the shifting trends for yourself.

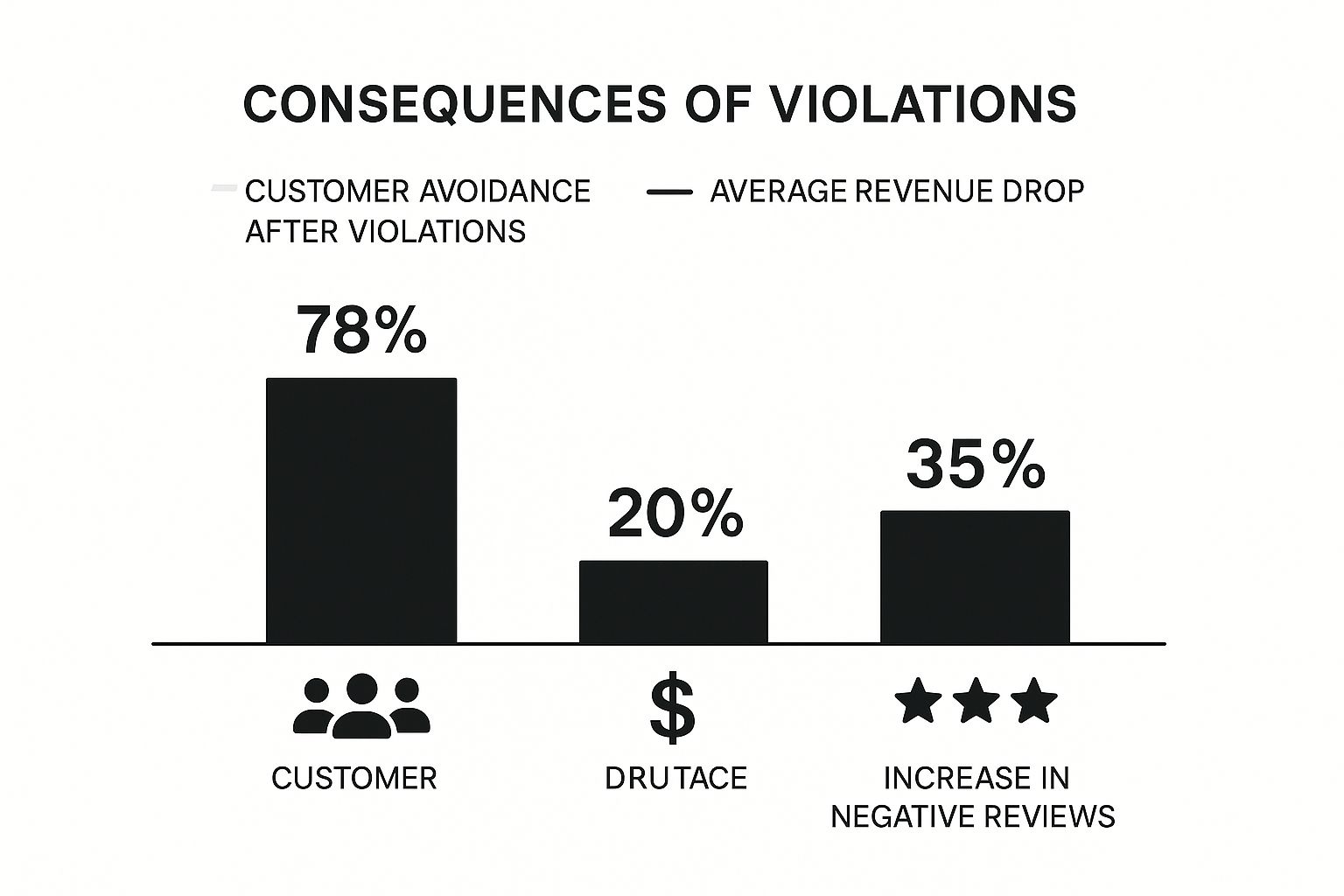

The fallout from these violations isn't just a slap on the wrist, as this data shows.

The consequences go beyond a simple fine—they hit your reputation and your revenue, hard.

To understand what inspectors are looking for, let's break down the most common critical violations, why they happen, and the real-world risks they pose.

Top 5 Critical Health Code Violations at a Glance

This table cuts through the noise to show you what inspectors flag most often, the everyday kitchen mistakes that cause them, and why they matter so much.

| Violation Category | Common Cause | Public Health Risk |

|---|---|---|

| Food Temperature | Leaving prepped food on the counter for too long; faulty refrigerators or steam tables. | Rapid growth of bacteria like Salmonella and E. coli, leading to food poisoning. |

| Cross-Contamination | Using the same cutting board for raw chicken and then salad greens; improper food storage. | Transfer of harmful pathogens from raw foods to ready-to-eat foods. |

| Staff Hygiene | Employees not washing hands after handling money or using the restroom; working while sick. | Direct spread of viruses and bacteria from hands to food, causing widespread illness. |

| Inadequate Sanitizing | Wiping down multiple surfaces with the same dirty cloth; sanitizer solution is too weak. | Surfaces that look clean are still covered in dangerous microorganisms. |

| Pest Infestation | Flies or rodents present in the kitchen; cracks in walls or open back doors. | Pests carry and spread a host of diseases, contaminating food and surfaces. |

As you can see, these violations are practical, daily risks that every restaurant manager needs a plan for. Let’s dive deeper into each one.

1. Improper Food Temperatures: The Danger Zone

Temperature control is your first and best line of defense. The "danger zone" is the temperature range between 41°F and 135°F (5°C and 57°C). In this zone, bacteria like Salmonella and E. coli don't just survive—they thrive and multiply at an alarming rate.

It happens all the time. A line cook prepping for dinner pulls a large container of sauce from the walk-in and leaves it on the counter for hours. Even in a cool kitchen, that sauce will quickly enter the danger zone, turning a good product into a serious hazard.

How to Stay Out of the Zone:

- Check, and Check Again: Use a calibrated food thermometer to temp hot and cold foods every two hours. Make it a non-negotiable part of the routine.

- Work in Small Batches: Only pull out what you can prep in a short window. Keep the rest safely chilled.

- Trust But Verify Your Equipment: Regularly service your refrigerators, freezers, and hot-holding units to ensure they're holding accurate temperatures.

2. Cross-Contamination: When Raw Meets Ready-to-Eat

Cross-contamination is a silent but deadly threat. It’s the unintentional transfer of harmful bacteria from one surface to another, and it can happen in a hundred different ways during a busy service.

Picture this: a chef slices raw chicken on a cutting board, gives it a quick wipe, then immediately starts chopping lettuce for a salad on the same board. All the bacteria from the raw chicken are now on the fresh lettuce, which won't be cooked. That’s a direct path for pathogens to reach a customer’s plate.

Cross-contamination isn't just about cutting boards. It can happen from hands, utensils, or even a splash of water. It's all about creating and enforcing strict separation at every step.

For a deeper dive into this crucial topic, you can learn more about how to prevent food contamination in our detailed guide.

3. Poor Staff Hygiene

Your team is your greatest asset, but poor personal hygiene can instantly become your biggest liability. Health inspectors watch employee habits closely because hands are the number one way germs spread in a kitchen.

An employee might take cash from a customer, then head back to the line to make a sandwich without washing their hands. Or someone who feels sick comes to work anyway and sneezes near the prep station. Simple actions like these can introduce viruses and bacteria into your food.

Hygiene Must-Haves:

- Stocked and Ready Handwashing Stations: Ensure every handwashing sink has soap, hot water, and paper towels. They must always be accessible—never blocked by a box or cart.

- A Clear Glove Policy: Train your staff on exactly when to change gloves. It should be automatic between tasks, especially after touching raw meat, taking out the trash, or handling money.

- A No-Nonsense Illness Policy: Be firm and clear: sick employees stay home. Period.

4. Inadequate Sanitization

Cleaning and sanitizing are two very different things. Cleaning removes visible grime. Sanitizing kills the invisible germs and reduces them to a safe level. A prep table can look sparkling clean but still be a breeding ground for bacteria if it hasn’t been properly sanitized.

A classic violation happens when a staff member uses the same sanitizing cloth to wipe down multiple surfaces without rinsing it or changing the sanitizer solution. A bucket of sanitizer that's been sitting out all day loses its effectiveness, meaning your team is just smearing germs around instead of eliminating them.

The Sanitizing Checklist:

- Master the Three-Compartment Sink: Ensure everyone knows and follows the wash, rinse, and sanitize steps for all dishes and utensils.

- Use Test Strips: Don't just guess. Use chemical test strips to make sure your sanitizing solutions have the right concentration to be effective.

- Sanitize on a Schedule: Create a simple chart for cleaning and sanitizing all food-contact surfaces—cutting boards, prep tables, slicers—throughout the day, not just at closing.

The Real Cost of a Failed Health Inspection

A failed health inspection is more than a bad day. The real damage from health code violations isn't just a fine; it’s a domino effect of financial, operational, and reputational blows that can haunt your business for years.

Too many owners think the fine is the only cost. That’s a dangerous mindset. The fines are just the price of admission to a much bigger problem.

Immediate Financial Penalties

The first hit is the direct financial penalty. These fines are designed to be painful enough to force you to fix things—fast. They can start at a few hundred dollars for minor issues but can easily climb into the thousands for critical or repeat violations.

Take Orange County, Florida, for example. Recent disciplinary actions show restaurants being hit with fines typically between $200 and $800. Some establishments were cited for three or more violations in a single visit, stacking up costs quickly. It's the health department's way of enforcing food safety. You can read more about recent restaurant disciplinary actions and their costs to see what this looks like.

But the fines are just the start. Other immediate costs can blindside you:

- Forced Closures: A single critical violation—like a pest problem or no hot water—can get your doors shut on the spot. Every hour you're closed is revenue you'll never get back.

- Mandatory Re-inspection Fees: After you’ve fixed the problems, you'll likely have to pay for the inspector to return and sign off on your work.

- Spoiled Inventory: If your walk-in fails and all that product enters the temperature danger zone, you could be forced to throw out thousands of dollars worth of food.

Hidden Operational Nightmares

The financial pain doesn't stop with fines and lost sales. A failed inspection throws you into a reactive, expensive scramble. This is where the hidden costs pile up, wrecking your workflow and draining your resources.

Think about how this plays out. An inspector flags your old meat slicer because it’s impossible to sanitize properly. Suddenly, you're facing an unexpected $3,000 bill for new equipment. Or they find your staff’s food handler certifications are expired, meaning you have to pay for immediate, unplanned training for the whole team.

The true cost isn't just the money you spend; it's the time, energy, and focus you lose. Instead of planning menus and serving guests, you're stuck in crisis mode.

These operational headaches often spiral into:

- Emergency Repairs: Needing to call a plumber or an electrician at premium, last-minute rates to fix an issue before the re-inspection.

- Deep Cleaning Services: Having to hire a professional crew for an emergency deep clean to deal with sanitation violations.

- Increased Staff Turnover: A stressful, chaotic environment driven by a failed inspection can convince good employees to leave, sticking you with hiring and retraining costs.

Long-Term Damage to Your Reputation

This is the most devastating cost of all, and it's the hardest to fix. Today, a health inspection score isn't just a notice on your window. It’s a public record, posted on health department websites and popular review apps for everyone to see.

A low score becomes a permanent stain. A potential customer sees a "C" grade next to your name or a list of critical violations, and they move on to the next option. Word spreads, and one bad report can erase years of hard work building a loyal customer base.

This is the intangible damage that can cripple a restaurant. The fine might be $500, but the lost business from customers who no longer trust you can easily run into the tens of thousands. Rebuilding that trust is a slow, difficult, and expensive journey that some businesses never recover from. The message is clear: the real cost of failing an inspection is far greater than any check you'll write to the health department.

Building a Proactive Food Safety Culture

Passing a health inspection shouldn't be a frantic, last-minute scramble. It should be the natural result of a strong food safety culture—a system where everyone, from the dishwasher to the head chef, owns their role in keeping guests safe. This mindset changes everything, turning compliance from a dreaded event into a daily habit.

Instead of waiting for an inspector to find problems, you build systems to prevent them. Think of this culture as your restaurant's immune system; it's always working in the background to fight off potential health code violations. It's about making the right way the only way of doing things.

This shift starts with clear, repeatable processes. When high standards are woven into the daily workflow, they become second nature to your team.

From Rules to Rituals: Daily and Weekly Checklists

The single best way to build consistency is with checklists. These aren't just tedious to-do lists; they are the blueprints for a safe kitchen. They eliminate guesswork from critical tasks and ensure important steps are done correctly, every time, no matter who’s working.

A well-designed checklist transforms abstract health code rules into concrete actions. It also empowers your team by giving them clear ownership over specific areas, building accountability.

Here are the checklists you need in place:

- Daily Opening & Closing Checklists: These cover the non-negotiables. This means checking fridge temps, testing sanitizer concentrations, and ensuring every handwashing station is stocked before the first customer arrives.

- Weekly Deep Cleaning Checklists: This is for jobs beyond a daily wipe-down. Think descaling the coffee machine, scrubbing the walk-in, and pulling equipment out to clean hard-to-reach spots.

- Task-Specific Checklists: For complex procedures, a dedicated guide is a must. A perfect example is a checklist for receiving deliveries—it should walk staff through checking temperatures, looking for signs of pests, and verifying dates on every product that comes in.

A food safety culture is built on a simple principle: small, consistent actions prevent big failures. Checklists are the tool that makes this consistency happen, turning good intentions into solid habits.

Sharpening Your Senses: Internal Audits

Why wait for an official inspector to tell you what's wrong? Running your own regular internal audits is one of the most powerful moves you can make. It means walking through your own restaurant with the same critical eye an inspector would.

This process lets you catch potential violations long before they become official problems. It’s like proofreading an essay before you submit it—you find the mistakes, you fix them, and you get a much better result. These self-inspections need to be scheduled and thorough.

Use your local health department's actual inspection form as your guide. That way, you’re looking for the exact same things they are. Focus on high-risk areas: temperature logs, food storage, and staff hygiene. Document your findings, create a clear plan to fix them, and follow up to make sure it gets done.

Training That Truly Sticks

Ultimately, a food safety culture is built on great training. The goal isn't just to make people memorize rules, but to build lasting habits. This means moving beyond a one-time orientation and committing to continuous, engaging education.

The impact is huge. The World Health Organization estimates that 600 million people get sick from contaminated food each year. Research shows that restaurants with formal food safety training can cut their violations by up to 50%, making a serious dent in that risk. You can discover more insights about food safety statistics and see just how powerful proper training can be.

To make your training effective, try these approaches:

- Micro-Learning: Forget long, boring meetings. Use short, 5-minute huddles before a shift to cover one specific topic, like how to calibrate a thermometer or the right way to use gloves.

- Visual Aids: Post clear, simple infographics where they matter most—like handwashing instructions right above every sink.

- Lead by Example: This is the most powerful training tool. When managers and owners follow every safety rule to the letter, it sends a clear message to the entire team: these standards are not optional.

Modern Solutions for Pest Control Violations

Few things trigger a failed health inspection faster than the sight of pests. A single fly in the dining room or kitchen is more than a nuisance; it's a red flag for inspectors, signaling deeper sanitation issues and an immediate risk to public health.

Many restaurants fall into a reactive trap, dealing with pests only after they become a visible problem. But the best defense against this critical violation is proactive, especially when it comes to flying insects, which are notoriously difficult to control once inside.

Why Flies Are a Critical Violation

It’s easy to dismiss a fly as an annoyance, but in a restaurant, it's a serious threat. Flies are experts at spreading germs. They breed in garbage and decaying matter, picking up pathogens like Salmonella, E. coli, and Listeria on their legs and bodies.

When a fly lands on a prep surface, a clean plate, or directly on food, it deposits these dangerous microorganisms, creating a direct path for contamination. This makes their presence an immediate food safety risk and a guaranteed health code violation.

Old methods for control are often just as problematic. Chemical sprays can contaminate food and air quality, while electric zappers are unsightly, noisy, and can scatter insect parts, creating a different contamination hazard. A better approach is needed.

The Power of Proactive Air Barriers

Instead of fighting flies after they get in, the smart solution is to stop them from entering in the first place. This is where modern fly fans come in. These devices are designed to create a constant, gentle air current that flying insects cannot penetrate.

Think of it as an invisible shield. The fan's soft, rotating blades create an unpredictable and disruptive airflow. A fly’s sensitive navigation system can't handle this turbulence, so it naturally avoids the area, effectively blocking it from landing on food or surfaces.

This method is a game-changer because it’s a deterrent, not a trap. It prevents the problem without chemicals, noise, or mess, making it an ideal solution for maintaining safety and a pleasant dining atmosphere.

By setting up these air barriers in key locations, you shift from a reactive to a proactive pest control strategy, which is exactly what health inspectors want to see.

Strategic Placement for Maximum Protection

To get the most out of fly fans, placement is everything. You need to think like a fly and identify the most attractive and high-traffic areas in your restaurant. Creating overlapping zones of protection ensures comprehensive coverage and makes it nearly impossible for flying pests to become a problem.

For an even more detailed strategy on pest management, check out our complete guide to fly control for restaurants. But for now, here are the essential zones to cover:

- Entry and Exit Points: The front door and any back delivery doors are primary entryways for pests. Placing fly fans or air curtains here creates the first line of defense.

- Dining and Patio Areas: Customer perception is critical. A fan on each table or spaced along an outdoor patio rail keeps the guest experience pleasant and pest-free.

- Buffets and Food Stations: Open food displays are a magnet for flies. Placing fans directly on or around buffet lines protects the food most vulnerable to contamination.

- Kitchen Prep Areas: Protecting the back of the house is just as important. Small fans near prep stations prevent flies from landing on ingredients before they reach the plate.

This layered approach makes your establishment an unwelcome environment for pests, drastically reducing the chances of a pest-related health code violation. It’s a simple, effective, and modern way to protect your food, your customers, and your reputation.

Answering Your Top Health Inspection Questions

The idea of a health inspector walking through your door can be stressful. But knowing what to expect and understanding your rights can turn that anxiety into confidence.

Preparation is everything. When you know the playbook for different inspection scenarios, you can handle them professionally instead of reacting under pressure. Here are the most common questions from restaurant owners, with direct answers.

What Happens If I Get a Bad Score on a Health Inspection?

First, don't panic. A bad score isn't a death sentence, but it does require immediate action. The inspector will give you a detailed report outlining every violation, broken down by severity. This report is your new to-do list.

For critical violations—issues that could make someone sick right away—you'll likely have a very short window, often just 24 to 48 hours, to fix them. For less urgent problems, you might have until the next scheduled inspection. Either way, a follow-up visit is almost guaranteed to confirm you've handled everything.

In extreme cases, like a major pest problem or no hot water, an inspector can shut you down on the spot until it's fixed. Since these scores are public, your best strategy is transparency and speed. Tackle every item on that list and keep communication open with your inspector. It shows you're taking public health seriously.

How Often Do Health Inspectors Visit?

This depends on your location, as every jurisdiction has its own schedule. As a general rule, expect an inspector to show up unannounced anywhere from one to four times a year.

That number can go up. If you have a history of violations (especially critical ones), you’ll land on their radar for more frequent check-ins. A customer complaint about foodborne illness will also trigger an immediate visit.

The best mindset is to assume today is inspection day. When you operate with that standard, a surprise visit isn't a scramble—it's just another day to show off your high standards.

If you're just starting out, you'll have an initial inspection before you can open your doors. They need to see you're set up for success from day one.

Can I Refuse Entry to a Health Inspector?

In a word: no. Health inspectors are officials with the legal authority to enter your restaurant anytime you're open for business. Turning them away is one of the worst moves you can make.

Refusing an inspection can lead to an instant suspension of your permit, a forced shutdown, and hefty fines. It’s not a battle you can win.

Instead of seeing them as an adversary, treat the visit as a learning opportunity. Walk with the inspector. You'll see your kitchen through their eyes, ask questions, and get a clear understanding of what needs to change. This cooperative attitude goes a long way in building a good relationship with your local health department.

Keeping pests out is a pillar of a great health score. Getting ahead of the problem is always better than reacting to a violation that can tarnish your hard-earned reputation. Modern Lyfe provides a simple, elegant solution with fly fans that create a pest-free dining area without chemicals or distracting noise. See how our solutions can help you protect your guests' experience at https://modernlyfe.com.