Food service hygiene standards are the non-negotiable rules for preventing contamination and ensuring every plate you serve is safe. This guide covers everything from handwashing and temperature control to equipment sanitation and pest management.

Following these standards isn't just good practice—it's essential for protecting public health and your reputation.

Why Modern Hygiene Standards Are a Business Imperative

Let's get straight to the point: basic cleanliness is the absolute minimum. In today's market, superior food service hygiene is a powerful part of your brand and a core business strategy.

We live in an era where one social media post can make or break a restaurant. A reputation for outstanding cleanliness is a major competitive advantage. Hygiene is no longer a back-of-house task; it's a visible signal of quality that your customers notice.

Beyond Compliance to Customer Trust

Strict hygiene protocols do more than just help you avoid fines. They are a direct investment in customer loyalty. When guests see a genuine commitment to cleanliness, it builds a powerful sense of trust that brings them back.

The data is clear. One survey revealed that 86% of guests consider cleanliness their top priority when choosing a restaurant, often ranking it above price, menu, and even service. Consistently meeting that expectation turns a first-time visitor into a regular.

The goal is to deliver a reliable dining experience that meets customer expectations and complies with food safety laws. This allows you to retain clients and ensure long-term operational viability.

The Financial Impact of Proactive Hygiene

Getting ahead of hygiene issues directly impacts your bottom line. It's not just about dodging health code violations or a foodborne illness lawsuit. A smart hygiene plan also reduces food waste by ensuring proper storage and handling.

Proven systems like HACCP are designed to identify hazards before they spoil ingredients or contaminate food. To learn more about this framework, see what HACCP in food safety means and how it can protect your business.

Ultimately, strong food service hygiene standards build a business that's sustainable, profitable, and respected.

Designing Your Food Safety Blueprint

To create a hygiene plan that works, you need to think like a health inspector but act like an operations manager. The goal isn't just to check boxes—it's to build a rock-solid system your team can rely on daily, even during the busiest rush. This blueprint is the foundation of your food service hygiene standards.

It’s built on three essential pillars. Each one covers a critical part of your operation, from the moment a delivery arrives to when a dish is served. Without a clear plan for each, you're leaving safety to chance.

Pillar One: Personal Hygiene Policies

It all starts with your team. A clear, non-negotiable personal hygiene policy is essential, and it must be written so there is zero room for misinterpretation.

This goes far beyond a "wash your hands" sign. Your policy must detail the what, when, and how of proper handwashing: use soap and warm water for at least 20 seconds, especially after touching your face, handling money, or returning from a break.

Your blueprint also needs strict, easy-to-follow rules on:

- Illness Reporting: Staff must have a clear, no-fault process for reporting symptoms like fever or an upset stomach, supported by a firm policy that they cannot work while sick.

- Uniform and Appearance: Mandate clean uniforms, require hair restraints like hats or nets, and prohibit jewelry that could trap bacteria or fall into food.

Pillar Two: Detailed Cleaning Schedules

A spotless kitchen is the result of a deliberate, documented strategy. Your cleaning schedule must break down every task, from daily surface sanitation to weekly deep-cleans of equipment like fryers and walk-in coolers.

For example, a busy café's daily checklist might include sanitizing the espresso machine, wiping down all counters with a food-safe solution, and mopping the floor. For a large catering operation, the list expands to sanitizing transport containers and deep-cleaning industrial mixers.

A great hygiene blueprint makes the correct way the easy way. When tasks are clearly defined, assigned, and scheduled, your team can build consistent habits that protect both your customers and your business.

Pillar Three: Safe Food Handling Protocols

Finally, your blueprint must map out the entire journey of your food, from delivery to the customer's plate. A major component is preventing cross-contamination, a common failure point in many kitchens.

This requires airtight protocols for:

- Receiving Deliveries: Train your team to check the temperatures of all refrigerated and frozen goods upon arrival and to reject anything outside the safe zone.

- Storage: Implement the First-In, First-Out (FIFO) method. Store raw meat on bottom shelves below ready-to-eat foods, and ensure every container is clearly labeled and dated.

- Preparation and Cooking: Enforce discipline—use separate cutting boards for raw proteins and produce, and constantly monitor cooking temperatures with calibrated thermometers.

The pressure for documented systems is growing. The global market for food safety compliance is expanding rapidly, driven by stricter regulations. Market projections show significant growth through 2033, highlighting the industry's focus on these practices. You can get more details by exploring the full market research on food safety compliance.

For a complete walkthrough, our guide on food safety guidelines for restaurants can help ensure your blueprint is as strong as possible.

Turning Hygiene Protocols into Team Habits

A great hygiene plan is useless if it stays in a binder. The real work is embedding those rules into the daily hustle of your kitchen. This is where you move from simply listing food service hygiene standards to building a true culture of safety.

The goal is to move your team beyond a passive "check-the-box" mentality. Handing a new hire a 50-page manual and expecting them to absorb it is a recipe for failure. Effective training must be active, engaging, and continuous. It’s about turning rules into reflexes.

From Manuals to Mindset

Real change happens when training is hands-on and directly connected to daily tasks. Don't just talk about cross-contamination; set up a practice station and have your team physically move from handling raw chicken to prepping a salad, correcting their technique in real-time.

A competency-based training approach is a game-changer. It shifts the focus from "did you attend the training?" to "can you perform the task correctly under pressure?" It's about demonstrating the skill, not just passing a quiz.

Here are interactive ideas that deliver results:

- "Spot the Hazard" Drills: Set up a prep station with deliberate mistakes—a dirty rag on a cutting board, raw meat stored above vegetables—and challenge your team to find them. It turns a dry topic into an engaging game.

- Peer-Led Demos: Ask a seasoned cook to show new team members how to calibrate a thermometer or deep-clean the ice machine. This reinforces their own knowledge and fosters a sense of ownership.

- Real-World Scenarios: Pose practical challenges. "A customer just reported a severe shellfish allergy, but their order is already on the grill. What's your immediate next step?" These practical questions are far more effective than written tests.

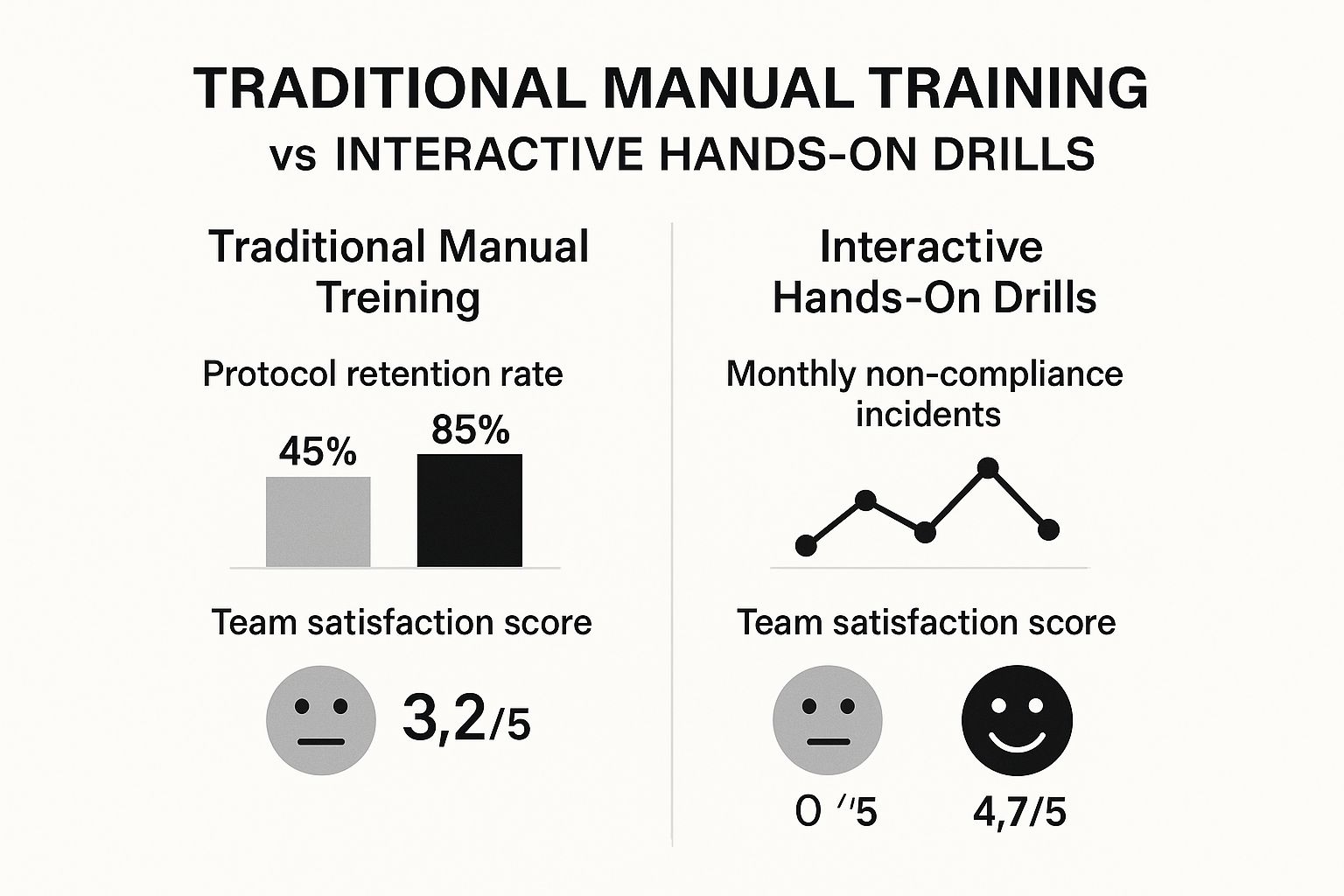

This infographic highlights the difference between outdated training and modern, hands-on methods.

The results speak for themselves. When people are engaged, compliance improves, and you build a more confident and satisfied team.

Fostering Ownership and Accountability

Great habits are forged through daily reinforcement and a culture where everyone—from the head chef to the newest dishwasher—feels responsible for safety. Your team must feel empowered to speak up about potential issues without fear of blame.

How you correct mistakes matters. If you see a cook wipe their hands on an apron instead of washing them, address it immediately but as a coach, not a critic. A simple, "Hey, let's hit the handwashing station before you touch those plates," reinforces the standard without creating tension.

Key Takeaway: Positive reinforcement is your most powerful tool. When the team aces an internal audit or someone handles a tricky allergy request perfectly, celebrate it. Make hygiene a point of pride for your whole crew.

Understanding the stakes is also crucial. Correcting these minor issues is how you avoid the most common restaurant health code violations that can cost you money and damage your reputation. When every shift is a chance to learn and improve, safety stops being a chore and becomes second nature.

Using Technology for Smarter Hygiene Management

Soggy paper logs and guesswork don't belong in a modern kitchen. Today’s technology offers a more accurate, efficient, and reliable way to manage food service hygiene standards. This isn’t about replacing people; it’s about giving them better tools to excel at their jobs.

Digital tools shift your approach from reactive problem-solving to proactive prevention. Imagine getting an alert that a walk-in cooler is warming up before it hits the temperature danger zone, saving hundreds of dollars in spoiled product. That's the power of integrating smart tech into your daily operations.

Automated Monitoring and Digital Checklists

The quickest win comes from automating tasks prone to human error. Automated temperature sensors are a prime example. These devices provide 24/7 monitoring inside your coolers and freezers, sending an instant alert to your phone if a unit's temperature rises.

This eliminates manual temp logs that are easily forgotten during a rush or filled out carelessly at the end of a shift. Instead, you get a perfect, time-stamped digital record that proves diligence and frees up your managers to focus on service.

Digital checklists on a tablet or app bring the same precision to daily sanitation.

- Time-Stamped Completion: Know exactly when a task was done. No more guessing.

- Photo Verification: Staff can snap a photo to confirm a task was completed to standard, adding a powerful layer of accountability.

- Never-Missed Tasks: The app flags incomplete items, ensuring nothing critical is missed before closing.

This move to digital compliance is the new industry benchmark. By 2025, leading operators will be expected to have traceable digital records for everything. Get more insights on future food safety trends at Navitas Safety.

The paper vs. digital debate is about accuracy and accountability, not just convenience. Here’s a direct comparison.

| Feature | Manual Tracking (Paper Logs) | Digital Tracking (Software/Apps) |

|---|---|---|

| Data Accuracy | Prone to human error, missed entries, and "pencil-whipping." | Automated data capture and required fields ensure high accuracy. |

| Real-Time Alerts | None. Problems are found only when someone checks the log. | Instant alerts for out-of-range temperatures or overdue tasks. |

| Accountability | Relies on trust and handwritten initials. Hard to verify. | Time-stamps, user logins, and photo verification create clear ownership. |

| Reporting & Audits | Requires manually sorting through binders of paper. | Generates instant, comprehensive reports with a few clicks. |

| Accessibility | Limited to the physical location of the logbook. | Accessible from anywhere via phone, tablet, or computer. |

| Task Management | Static checklist; easy for tasks to be forgotten or missed. | Dynamic task lists with reminders and automated escalation for overdue items. |

While paper is familiar, digital systems provide a level of oversight and risk prevention that a clipboard can't match.

Creating a Perfect Audit Trail

Beyond daily tasks, this software creates a single, organized hub for all your hygiene data. When the health inspector arrives, you're no longer scrambling to find a specific logbook.

With a few clicks, you can pull up detailed reports on temperature history, cleaning schedules, and staff training. This level of organization demonstrates a deep commitment to your food service hygiene standards and builds instant credibility.

Investing in this technology is a strategic move to improve consistency, lower risk, and protect the reputation you've worked so hard to build.

How to Ace Your Next Health Inspection

A health inspector's visit doesn't have to be stressful. When you treat every shift like it's inspection day, it becomes a routine check-in, not a high-stakes exam. The secret is to stay ready so you never have to get ready.

Thinking Like an Inspector

The best way to prepare is to think like an inspector. They are trained to spot small details that signal larger problems. By conducting your own internal audits, you can catch these red flags long before an official visit.

Make a habit of performing regular, unannounced walk-throughs. Look at your operation with a critical eye, focusing on common violations.

- Temperature Danger Zones: Use a calibrated thermometer. Are walk-ins and coolers holding below 40°F (4°C)? Is hot food on the line consistently above 135°F (57°C)? Log everything.

- Cross-Contamination Risks: Notice the small things. Are the tongs for raw chicken resting near fresh produce? Did a cook wipe their hands on an apron instead of washing them?

- Sanitizer Concentration: Check your sani-buckets. Is the solution mixed correctly? Too weak is useless; too strong is a chemical hazard.

A proactive internal audit isn't about finding fault; it's about finding opportunities. Every issue you catch and correct on your own is one less violation on an official report.

The Power of Meticulous Records

Nothing builds an inspector's trust faster than organized, up-to-date records. It proves you're in control and take food safety seriously.

When they ask for temperature logs or training certificates, you should be able to produce them instantly. Fumbling through a messy binder sends the wrong signal.

This is critical as regulations become stricter. The European Food Safety Authority (EFSA) is rolling out new guidelines for novel food applications starting February 1, 2025, part of a global trend toward tighter compliance. Thorough documentation is no longer optional. Learn more about these changes in the 2025 global food regulatory updates at Reach24h.com.

By running tough self-inspections and keeping flawless records, you turn an inspection from a stressful test into a routine validation of your high standards.

Common Food Hygiene Questions Answered

Even with great systems, real-world questions about food service hygiene will always come up. Giving your team clear, direct answers keeps them confident and your operation safe. Here are straightforward answers to some of the most common issues.

How Often Should I Update My Hygiene Standards?

Your hygiene standards are a living document, not a static file. Conduct a full review at least once a year to ensure everything is still current.

However, you should also update them immediately following any major operational change. A new menu, a new piece of equipment, or updated local health codes all trigger a review. If a health inspector flags an issue, use their report as a direct guide for what to fix immediately.

What Is the Single Biggest Hygiene Mistake?

The most critical and common issue is inconsistent temperature control. This includes everything from a food delivery sitting on the loading dock too long to a cooler running a few degrees too warm. Health departments call this a failure of "time/temperature control for safety" (TCS), and it's a major red flag.

A very close second is inadequate staff training on preventing cross-contamination. Small, avoidable mistakes—like using the same tongs for raw and cooked foods—can have serious consequences.

Are Gloves More Sanitary Than Bare Hands?

Not automatically. Gloves can create a false sense of security. Their effectiveness depends entirely on how they are used.

- Change them often. Gloves must be swapped between tasks, especially when moving from raw to ready-to-eat foods.

- Wash hands first. Staff must wash their hands thoroughly before putting on a new pair. A glove is only as clean as the hand inside it.

- Replace if damaged. A torn glove is a serious contamination risk and must be replaced immediately.

Proper, frequent handwashing is often safer than improperly used gloves. The key is rigorous, ongoing training on both.

What Are the First Steps After Failing an Inspection?

First, don't get defensive. Use it as a learning opportunity. Review the report with the inspector to ensure you understand every violation. If you can fix any "critical" violations on the spot, do so immediately—it shows you're proactive.

As soon as they leave, create a detailed action plan. Assign each corrective task to a specific person with a firm deadline. Communicate the plan to your team and conduct immediate retraining on problem areas. Document everything you fix and maintain open communication with the health department to show your commitment.

Keeping dining areas free from pests like flies is a crucial and visible part of your commitment to hygiene. MODERN LYFE offers stylish, effective fly fans that protect your food and enhance guest comfort without disrupting your decor. Explore our collection of fly fans at modernlyfe.com and create a more pleasant, pest-free environment.